Well, first a big “Hurrah!” Well done Team Oracle USA. What an amazing spectacle. From being almost out at 8-1 (including a 2 race penalty from pretrials?!), they won 8 straight. Magnificent duel in flying machines.

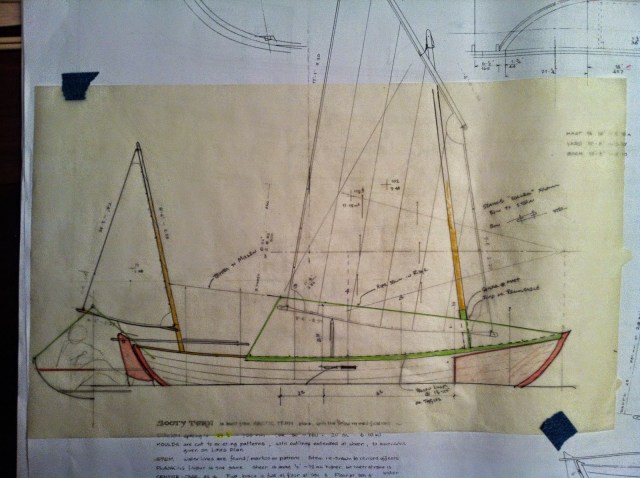

Back to a more “primitive” boat and building: no carbon so far.

The main yard and mizzen mast birdsmouth spars were lead ups to the “biggie”, main mast. The practice was needed and I believe it paid off. While all spars need the final sanding, they have been 16 sided for that step. The other steps were:

- for the 16′-10″ spar 8 staves were cut on the table saw out of a 5/4x6x18′ douglas fir board. Stave width, height, and taper were derived from Duckworks’ Calculator Program.

- ganged together the staves were then tapered with a jack plane. Some sort of jig using either the table or circular saw would have been quicker, but I wanted to sneak up on the final taper. I also like planing.

- a thin coat of epoxy was painted onto what would be the interior face of the staves.

- then thickened epoxy was brushed onto the “beaks” of the staves.

- the base octagonal plug with feathered or crowned ends was inserted between the staves and actually aided in the glue up.

- a second pair of hands helps tighten zip ties every 4-6″.

- I spent perhaps an hour confirming the straightness of the glued and zipped spar. A tight string run over the mast proved very helpful toward keeping things true. For something larger I’d want to make a more exacting jig to hold everything true.

- I left the setup overnight. Cut the ties this morning.

|

| Abstract No. 2 |

- Knocked the stave edges to 8 sides. With a spar jig turned that to 16 sides. Those residual corners were hit lightly with the plane.

|

| Almost 17′ and, thankfully, true. |

|

| Sap streaks I had intended to turn in, but didn’t catch it. |

|

| 8 sided cherry plug. |

|

| Overall. Final base plug yet to be added. |

- I almost forgot to add that I had estimated the weight of this spar to be 22 lbs. The unsanded/ unfinished spar is 19 lbs. 4 oz. On target!

- And so, sanding remains to suit for finish. I haven’t decided on this method: drill with drum, sanding longboards, or hand sanding by “shoe shine” with a sanding belt. Perhaps all of the above? I’d like to figure a simple way to rotate the mast like a lathe. We’ll see … I now need a boat for these sticks.