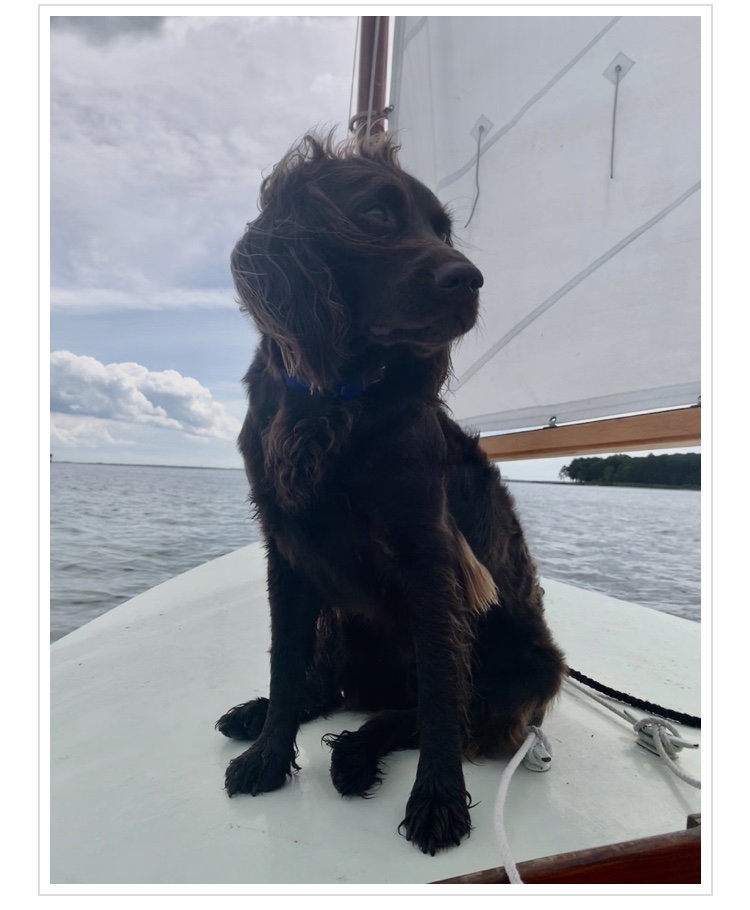

Please pardon me as I ask for this simple indulgence. We said goodbye to our Huckleberry yesterday. Our beautiful little brown “puppy” would have been 10 in March. We’re wrecked. However, I’m compelled to honor him somehow. Perhaps here is a start towards that end. He gave us so much.

There are dog people out there, some cat people do exist, and then there’s everyone else. I’ve a hunch only dog lovers will understand. So, I won’t be persuaded a gecko is your friend. Oh, you have a snake? Well, never mind then! Sorry, but it is oft told that the dog is man’s best friend and so it has been since the dawn of time. Mine was a valiant and devoted buddy. My constant shadow, Huck was a long-legged, flat-coated Boykin Spaniel. He loved us and oh how we loved him. Never once was he made to stay overnight in a kennel. But how could you do anything? Didn’t you miss traveling? To where? The Bahamas, Mexico, Singapore, Croatia … All would have only been somewhere without my puppy. Frankly, I would have hated that. Life was so rich with our Huck.

He ran his race to the very end: Two emergency vet visits and three office appointments. He saw four different vets who were slow to figure things out. Huck’s bouts of extreme lethargy and loss of balance taunted him, then he’d fight to regain some lost ground. He had arthritis developing, neurological issues, but ultimately his kidneys were failing him. Who knows if the half-dozen meds prescribed helped or hurt. I do know each doc visit was a trauma for him.

Boykins are not generally a “relaxed” breed. They need to be in the field and in the chase. Fortunately, we could let him roam; our gravel road leading to the house is a half mile from the pavement. It makes for nice walks at daybreak. I don’t believe he ever ventured to the road without me. I suspect he didn’t want to be far from his people. He had responsibilities after all. Several of our neighbors loved on him. One neighbor relayed the pooch would stare at her kitchen window until treats appeared. Out of biscuits a couple times she said she felt compelled to hide! He could be demanding. An alpha dog, he often challenged the master/pet contract. Perhaps he had it right with three families doling out affection and doing his bidding. Huck thought we all were his. Every day he’d make his rounds to make sure all was well on the estate.

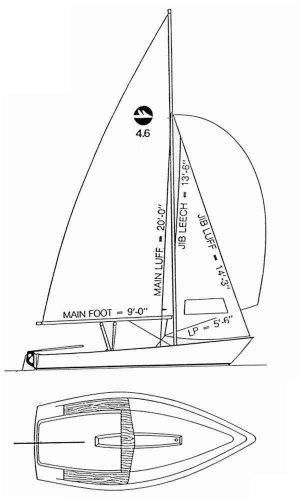

No, “relaxed” is not the breed. Huck wasn’t, unless he was sailing. That boy could be frantic at the ramp or pier, but once aboard, he was chill. Rarely did I leave him behind while sailing out of the backyard. If ever I did, you could hear all the way up the river what one nice neighbor called his “sad song”. He was mostly quick to forgive. I always felt guilty … and was. He genuinely loved sailing. Last September I sold the go-to boat, my wife’s Beetle Cat. Anxious to find another daysailer, within days I found an old Harpoon 4.6 and dragged it home. Sadly, Huck’s legs were becoming too unsteady, like mine I suppose. Given his dog years, we clocked about the same age. His adventures were likely greater. What a dog! Our last sail together was for a week in Maine this past August. We slept in the bottom of our small UNA accompanied by four friends in their three boats. It was heaven. Huck and I shared a common tempo when cruising. Wasn’t it a hassle rowing the pup ashore morning and evening? No, I enjoyed it thoroughly. We were a team. He the watchman, me his swabby. I gladly put my back into the oars. I felt it a privilege. His ongoing illness had added a few pounds. Our last week together required carrying his now 60 pound frame down to the yard for fresh air and dog business. My recently torn knee did protest, but again, I didn’t mind. I like to think he wouldn’t have either. We just took it slow down the steps and back. Oh, how I wish I had just one more chance to carry him. My precious buddy, such a sweet little soul was he.

Everybody, I’m talking dog folks now, loved him. Girls of all ages fawned over his “mohawk” and asked to pet him. His “sprouts” appeared in his second or third month and grew brighter and wilder with each year. When the UPS driver arrived, old Huck would bark out his warning. He sounded fierce, yet all the while his docked tail was ticking at peak rpm. Figuring he had the right brown uniform, he’d climbed up into that brown truck and asked for treats from Orlando. Huck received that love almost every other week for the past four years. The FedEx woman, on the other hand, would crack her window, chuck out a handful of biscuits to distract and hustle her package to the porch. She never believed Huck wouldn’t bite. He never did. All bark, just like his swabby.

There’re too many stories to tell: panic from a copperhead bite as a puppy, a pack of firecrackers eaten at 2 months, getting skunked 3 times!, driving 70 mph and honking through red lights to see the emergency vet to sew up a sailing injury. I was thankful he still desired to go …

He was a beautiful match for this sailor, but his tank was nearly empty. He could barely move. He couldn’t have but a day left in him, and he was in such pain. I felt I had no right to have him put to sleep.

I must end this. Below is a previously shared video. Wait or go to the point where the music stops. It’s just water lapping, buffeting wind, salt air and my puppy. It illustrates why we were such a good pair, kindred souls maybe. Isn’t there a saying about dogs and their owners being alike? I’d hate to disparage such a fine fellow as my Huckleberry. The sad truth is there will be no more waking early together nor walking down our hallway to inhale the new day, no feeding of breakfast while making coffee. No rubbing down his old shoulders and back before the first sip. He taught me how to serve better, and I loved him for it. No more will we “hike” up the road and back. It was beautiful to watch him dash through a field or give chase through the woods … or rest his chin on the gunnel listening to the water, smelling the marsh. Watch this clip if you will. There is nothing like a water dog and there will never be another like Huckleberry. I miss him so. Rest well my dearest Puppers.