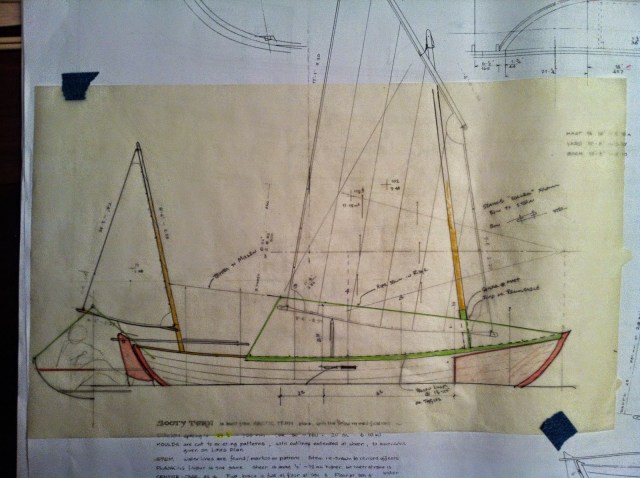

In reality there are no drawings for the Sooty. It is a stretched version of Oughtred’s “Arctic Tern” by 18″. The moulds are pushed further apart and the shear is adjusted up maybe 1/4″. So, you purchase the Arctic plans and a Sooty “supplement” which includes a lines plan and offsets. All other detail is derived from studying the Arctic plans seen here:

I will build the yawl rigged boat with

birdsmouth spars, closed gunwales, and decked fore and aft. Of course, any of that can change. I’m actually well along in the build and neglected to take many photos so far, but some will show the process and progress so far.

|

| Made a stack of “clothes pin” clamps (32) |

|

| The building platform. |

|

| 1/2″ OSB painted light grey for moulds. |

|

| Moulds cut and mounted. |

|

| Battens for plank alignment. |

|

| Aft stem & keelson added. Note mould bracing. |

|

| Not so fine platform extension for stem. |

Stems are epoxy laminated douglas fir. Keelson is also fir. The centercase slot was cut on the table saw before mounting. I taped a copy of the stems on flat OSB taped over that to release from epoxy, and screwed short block for lamination clamps.

|

| Aft stem formwork. |

|

| Formwork close up. |

|

| Inner stem or apron glued up. |

|

| Outer stem glue up. |

Since I do not have enough long reaching clamps, I waited for inner stem to dry to use it as the form for the outer. Make sure to add clear plastic tape or plastic between the two!

While I waited for the plywood order, I began the spars. I’ll allow Duckworks to explain the particulars.

These too are of douglas fir. The preferred sitka spruce proved too dear by a cost factor of seven! I reality the weight savings is negligible in birdsmouth construction and I like the amber tones of fir better. Fir also shows some strength advantages. I questioned the 33#/cubic foot weight typically specified, so I weighed a 2x4x12′ board and interpolated to #/cu. ft. I got 33.4#/cf.

The Duckworks calculators are very helpful. There are calcs for proper diameter and stave thicknesses based on a solid spar. The main mast is specified as a 3″ diameter spar. The calcs add 15% for a 3.33″ diameter or just more than 1/4″. Thus far I have constructed the mizzen mast and yard. The booms will be made solid due to their weight is low and all the blocking for cleats, pulleys, etc. would fill the hollow spar. I also thought a more bullet proof spar here would be desirable.

|

| CADD drawings of spar and a cut off portion. |

|

| 16 sided spar and cherry plug. |

|

| Mizzen mast base with slot as a weep. |

|

| Open bench allows spar clamping and shavings to fall. |

The open bench is 20′ long. I saw this great arrangement on Andy Kane’s photo collection. I built mine from a discarded pallet and four 10′ 2x4s. The reuse makes one feel you are cheating the expense. The stack of clamps were made from scraps left over from my SOF kayak frames. Having the bench outside keeps the dust outside too.

Other parts I’ve started are the rudder head faces. These are from cherry boards which I lugged from city to city and house to house from Houston to Virginia. I knew one day I’d find a project to do the boards justice. I enlarged the rudder drawing, plotted sheets (8.5×11), taped them and made an OSB template. The cherry was just shy of the needed width, so I epoxied a joint where the faces will hold a solid piece inside.

|

| Rudder layout. |

|

| Layout on cherry. |

|

| Rudder head template. |

Lastly, I’ll show a screw up. Despite my efforts to place the birds mouth yard in a jig to keep it true, in tightening the zip ties I must have pushed/pulled too hard and put a crook in the spar’s end. I was ready to make another when cooler heads prevailed. I realized the spar was straight on one axis. A delicate slice along 4′ of the crooked axis allowed for realignment and work to go on. In an odd way I’m proud of the small scar left in the spar

|

| Zip tie waste. |

|

| Saw surgery along curved stave. |

|

| Slice before epoxy. |

I’ll photo the finished spar later. A second boom and the main mast need to be built, but we have the hang of it now.